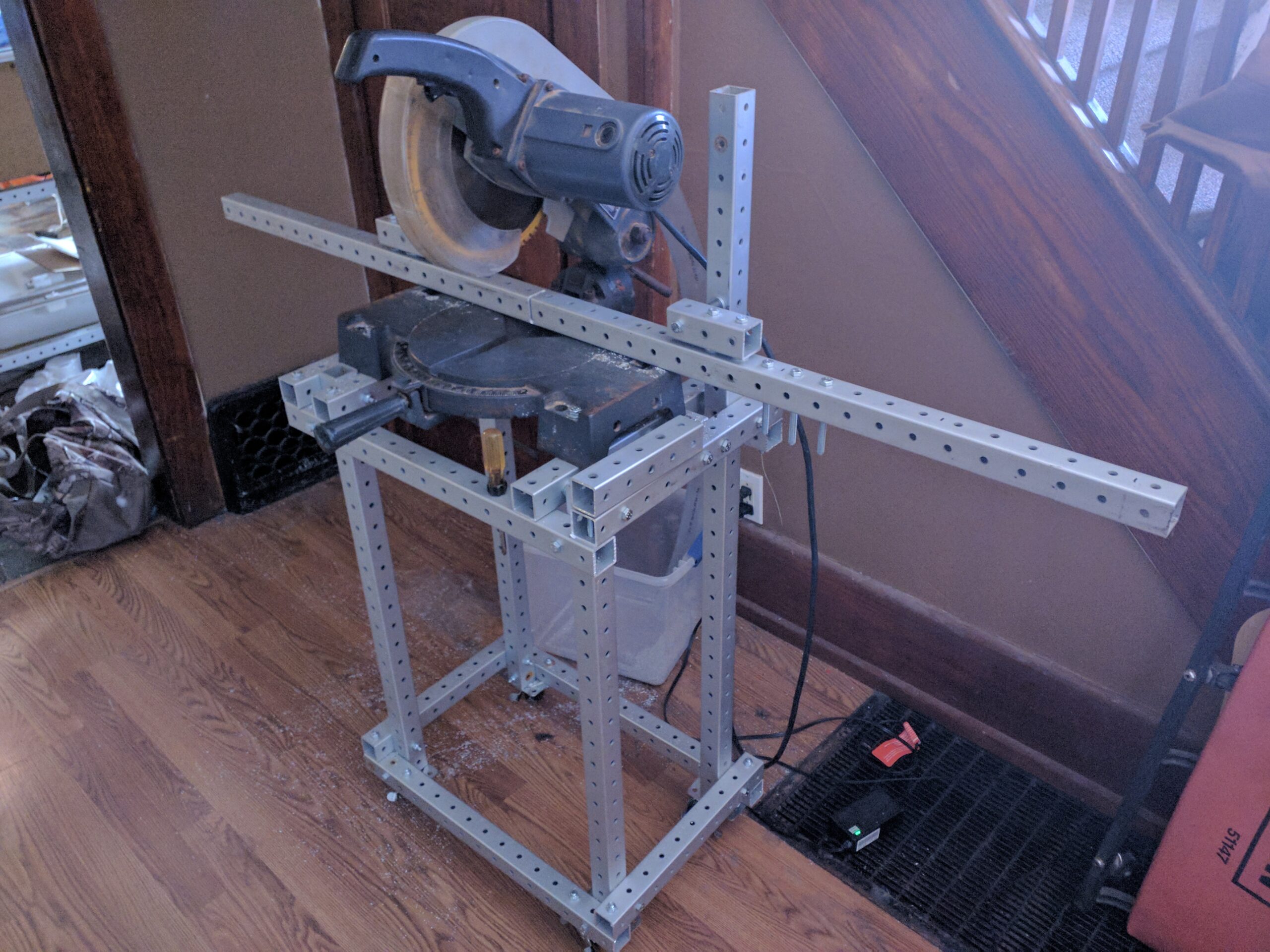

Profile

Replimat frames are constructed of individual frame sections with a square profile or cross-section. All frame sections share the same profile, which is 40mm across each side. Frames of larger or smaller profile sizes may be produced, and continue to work with all of the construction techniques found here.

Hole Pattern

Holes are centered on each face of the frame and spaced regularly in a repeating pattern at a distance equal to the width of the frame. This geometrical arrangement allows the frame members to reliably produce rigid joints in three dimensions.

Lengths

Frame lengths are intentionally limited to 2, 3, 4, 5, 10, 15, 20, 25, 30, 35, 40, 50, 60, 80, and 100 holes per side. These lengths have been chosen to allow for the creation of all necessary joint configurations (using lengths 2, 3, 4, and 5) as well as to allow for lengths with a center hole and lengths which are evenly divisible by two. The reduced set of lengths allows for improved reuse from project to project, easier identification in photographs and diagrams, and simpler production, handling, and shipping.

Nuts and bolts

Frame sections are joined together using three lengths of bolt, suitable for 1, 2, or 3 stacked frames and share a single size washer and nut.

Tools

Frame assembly requires two 13mm wrenches. A socket wrench or battery powered electric socket wrench are highly recommended for quick and easy [dis]assembly.

Joints

Three frame sections can be joined with three nuts and bolts to form a strong three dimensional joint orienting each frame section perpendicular to the others. Other joining techniques allow for triangular and hinged joints, which are sufficient to build several useful linkages including the Peaucellier–Lipkin linear motion linkage, Jansen’s linkage, leading link suspension, and more.